DIY in-line monitoring of Villermaux-Dushman mixing characterIsation

A common technique used to experimentally characterise mixing timescales is the well known “Villermaux-Dushman” competing chemical reaction system. With this system, multiple reactions compete in parallel, resulting in an iodine concentration being produced which is linked to mixing timescale. Since iodine is coloured, the concentration can be easily determined via optical absorbance measurements.

In studies quantifying the performance of in-line mixers, a sweep of flowrate conditions and mixer geometries is typically required. Performing this manually is both tedious and opens up the opportunity for result variability on account of both a. literature detailed sensitivity of the VD technique, and b. slight setup variations. Tracking down and diagnosing the latter can be frustrating.

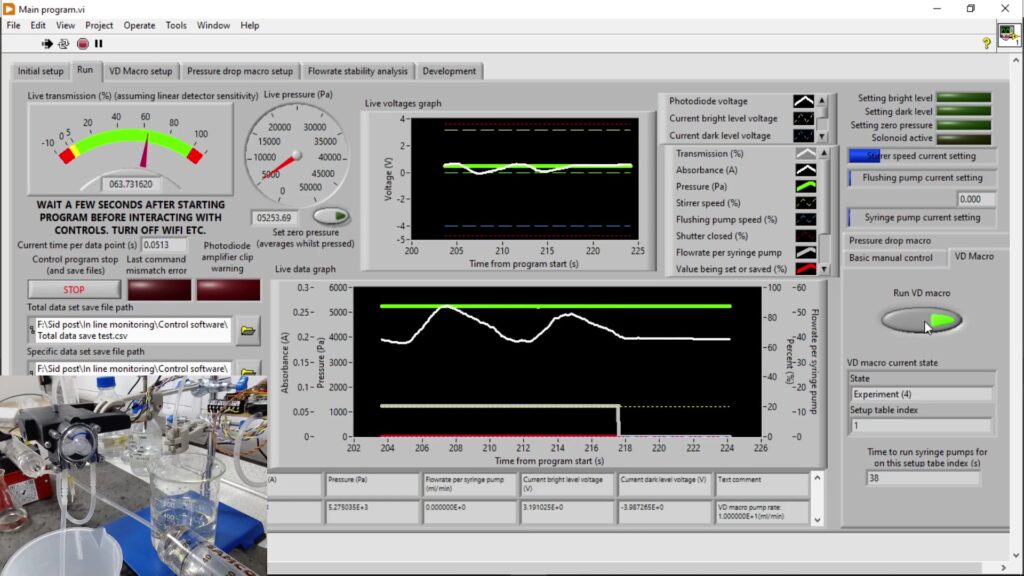

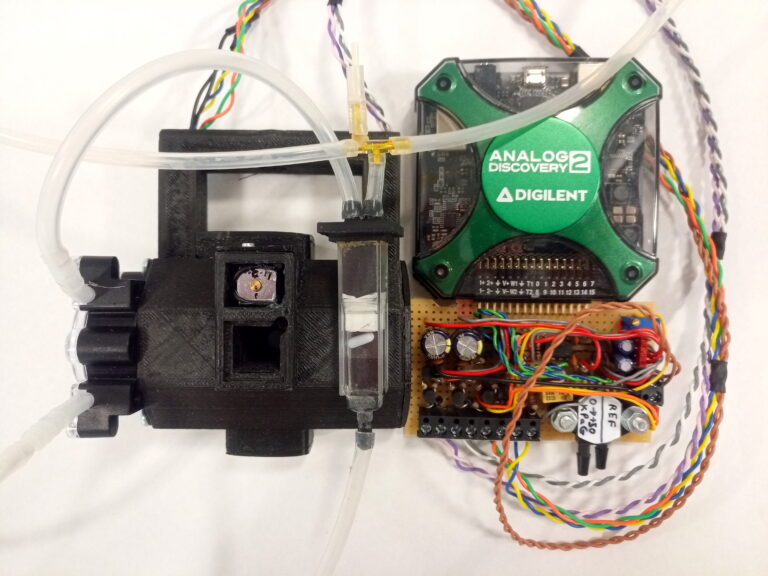

During Richard’s PDRA in the Green Nanomaterials Group in the Department of Chemical and Biological Engineering at The University of Sheffield, he developed and implemented a DIY low cost in-line absorbance setup for this chemical reaction system utilising disposable cuvettes, off the shelf LEDs/detectors and a 3D printed housing (shown above). It also features an integrated stir bar motor to ensure final mixing completion, hardware for automatic bright and dark level setting and a pressure sensor for characterising mixer pressure drop for energy input and/or VD reaction system concentration choice. This was fully automated via a program written in NI LabVIEW (shown below), which additionally controls a pair of syringe pumps. This setup allows the rapid characterisation of micromixer systems and/or sources of experimental variability to be easily identified. Common laboratory syringe pumps were found to be especially problematic in terms of flowrate stability.

A publication which details the in-line setup being used for micromixer characterisation is under preparation. This system was presented at the “Mixing 17” conference (2-5 July 2023, Porto, Portugal). The very first prototype was 3D printed via Luc Dewulf in the Sheffield iForge makerspace prior to the arrival of a new 3D printer – the assistance is gratefully acknowledged.